How to make the battery packs in parallel by modular

Making battery packs in parallel by modular solution

The existing problems when two or more battery packs are in parallel:

High voltage battery packs automatically chare the low voltage of the battery packs. At the same time, the charging current becomes very large and even fluctuates as every single battery pack has different internal resistance, voltage and capacity, which might damage the BMS.

At present, most companies use current-limited modular to control charge current for each battery packs. However, this is potential to damage the BMS.

Current-limited modular allows the BMS on protection when the charge current is large. Therefore, the all-power system cannot discharge and charge.

If the battery packs modular are applied to the electric motorcycle, ebike, robot, telecom storage, they are not convenient to replace one battery pack of the modular.

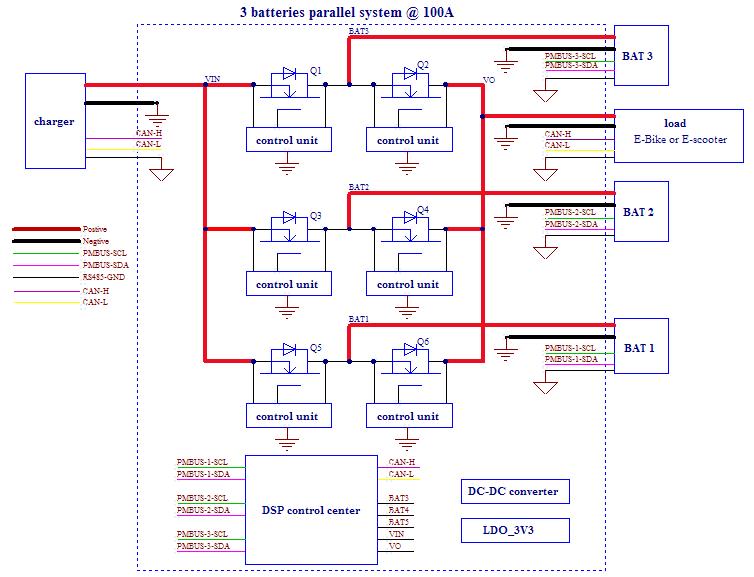

The LIAO battery team designed one parallel modular. More details of our parallel modular are as summarized below:

Our parallel modular supports two or more battery packs and works simultaneously. The user can use one battery pack or more battery packs at any time.

The continuous discharge current is no more than 100A of battery pack modular.

The voltage is no more than 110V of battery pack modular.

Our parallel modular can support CANBUS and RS485 communication. However, each battery pack should have a unique ID.

Our parallel modular is widely used for shared electric bike, electric motorcycles, mobile storage equipment, and portable cleaning equipment, among others.

The working model of our parallel modular

- Charge mode: The lower capacity battery pack will be charged in priority. When the voltages of the two battery packs or one battery pack are the same, the current distribution ratio is equal to the battery capacity ratio. For instance, a 40Ah battery in parallel with a 60Ah battery pack as the 40Ah battery pack accounts for 40% of the charger’s output power while the 60Ah battery pack accounts for 60% of the charger’s output power. The charging current range for each battery is 0-50A whereas the dual battery is 0-100A.

- Discharge mode: High voltage battery pack will give discharge in priority. When two battery packs voltage are equal to two batteries simultaneously to the load discharge, the current distribution ratio is also considered to be equal to the battery capacity ratio. For instance, a 40Ah battery in parallel with a 60Ah battery pack where 40Ah battery packs account for 40% of the load input power while the 60Ah battery pack accounts for 60% of the load input power. Accordingly, the discharge current range for each battery is 0-150a while the dual battery is 0-300a.